Hammer Mill

What is hammer mill?

TFS series hammer mill is a new type biomass hammer mill, which is suitable for crushing of grain, crop, Chinese herbal medicine, straw, potato, seasoning, etc. GEMCO hammer mill is small scale and multi-purpose, it not only can crush corn, sorghum, rice, soybeans and other kinds of food, but also can crush soybeans, fresh sweet potatoes, fresh potatoes, pepper, Chinese herbal medicine and so on. Our hammer mill can be equipped with sieve with different specifications according to the needs of users, in order to process materials into variety parameters.

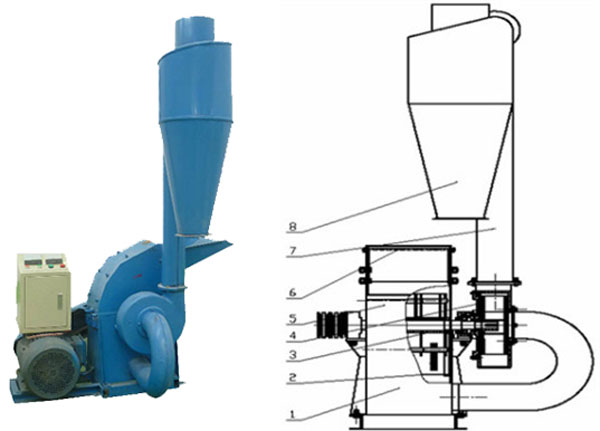

This biomass hammer mill can process wood, fresh sweet potatoes, corn, grain, plant hulls, corn, wheat, soybeans, and other biomass materials into powder with 3-5mm diameter, so that the material can be used to make pellets. GEMCO wood hammer mill can be divided into two types, hammer mill without cyclone or with cyclone, you can choose according to your needs.

Advantages of GEMCO hammer mill

- Automatic mechanical feeding: the operation is convenient and quick, and the production efficiency is high;

- Smooth work: continuous grinding, balanced processing, safe and reliable;

- Durable: steel structural components. The material is solid and reliable, use high-power self-aligning bearings, long service life;

- Low cost: low power; excellent cutting tools, double blade, service life can up to 500 to 1000 hours, and can be repeated regrinding;

- Easy to move: trailer type hammer mill can be produced according to customer requirements, to facilitate field production

Working principle of GEMCO hammer mill

The machine breaks the material into the crushing chamber through a high-speed hammer, under the influence of centrifugal force, the crushing powder is sent out through the sieve hole under the centrifugal pressure of the rotor and the suction of the fan。 The powder particles that are not through the sieve repeat the process until they can be sent out through the screen.

| 1. lower body | 5. upper body |

| 2. sevier | 6. feeding port |

| 3. rotor | 7. discharging outlet |

| 4. air fan | 8. cyclone |

Hammer mill specification

We have both electric motor hammer mill and diesele engien hammer mill for our customers to chhose. Generally, the electric motor is necessary, but if your working area is difficult to get electric power, you can choose our convenient diesel engine hammer mill. Following is their specification.

Electric motor hammer mill

| Model | Output Capacity (kg/h) | Power |

Screen mesh (standard) |

Hammer Quantity | Diamesion | Weight(kg) |

|---|---|---|---|---|---|---|

| FSP158B | 100-200 | 2.2 KW Single phase | 4 | 16 | 750*450*730 | 75/85 |

| FSP198B | 200-400 | 3 KW 3 phase | 4 | 16 | 1000*750*1120 | 120/135 |

| FSP198B | 240-400 | 4 KW 3 phase | 4 | 16 | 1000*750*1120 | 120/135 |

| FSP420B | 800-1000 | 7.5 KW 3 phase | 5 | 16 | 1200*1000*1220 | 250/270 |

| FSP420B | 800-1000 | 11 KW 3 phase | 5 | 16 | 1200*1000*1220 | 300/320 |

| FSP420A15 | 800-1000 | 15hp | 5 | 16 | 1650*800*1120 | 370/390 |

| FSP420A22 | 800-1000 | 22hp | 5 | 16 | 1650*800*1120 | 390/410 |

| FSP500B-28 | 1000-1200 | 11 KW 3 phase | 5 | 16 | 2200*1000*1020 | 470/500 |

| FSP500B-28 | 1000-1200 | 15 KW 3 phase | 5 | 16 | 2200*1000*1020 | 500/530 |

| FSP500A-28 | 1000-1200 | 22hp | 5 | 16 | 1650*800*1120 | 370/390 |

| FSP500B-40 | 1200-1700 | 22 KW 3 phase | 5 | 24 | 2200*1050*1020 | 710/755 |

| FSP500B-40 | 1200-1700 | 30 KW 3 phase | 5 | 24 | 2200*1100*1270 | 800/835 |

| FSP500A-40 | 1200-1700 | 55hp | 5 | 24 | 2250*1150*1270 | 995/1065 |

| FSP500B-60 | 1700-2100 | 37 KW 3 phase | 5 | 36 | 2300*1150*1350 | 1150/1230 |

Diesel engine hammer mill

| Type | Capacity (Hp) | Output (kg/hr) | Weight (kg) | Package Size (mm) |

|---|---|---|---|---|

| TFS420 | 15 | 250-500 | 370/390 | 1650*800*1120 |

| TFS420 | 22 | 250-700 | 390/410 | 1650*800*1120 |

| TFS500 | 55 | 800-1100 |

Cyclone: 125/145 Hammer Mill: 310/330 Diesel Engine: 650/590 |

2700*900*1700 1150*800*1270 1500*1050*1320 |

Why choose GEMCO hammer mill

At present, GEMCO has got a number of core patented technology in biomass granulation, in addition to household small biomass pellet machine and hammer mill, we also provide our customers with integrated pellet plant and various of spare parts like flat and die. What’s more, we also have the ability to provide customers with all-round three-dimensional services from design, manufacturing to installation, commissioning and training. Up to now, we have built several turnkey biomass pellet production lines by ourselves in Eastern Europe, South East Asia, South Asia, northern Europe, Western Europe, North America and South Africa. GEMCO hammer mill is your ideal choice to crush agricultural raw materials.