What you need to know while choosing a wood pellet machine?

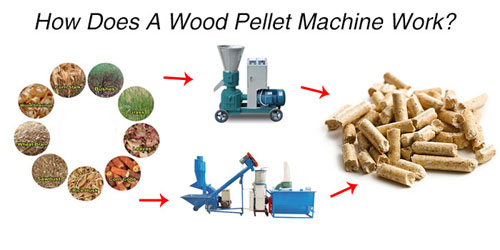

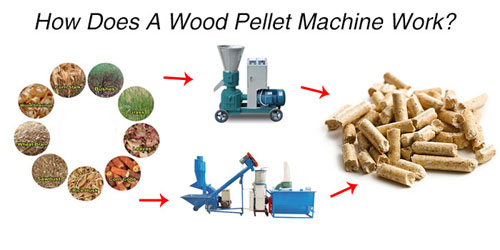

In recent years, it is easy to find that in many places, they no longer uses coal for home heating, instead, a new biomass pellet take it’s place. It fact, biomass has taken the place of coal not only in the area of home heating, but also in industrial boiler and other areas. GEMCO wood chip pellet machine is used to produce biomass pellet. Wood chip pellet machine can produce wood pellet, which is a kind of clean and new kind of energy.

Take the weather factor into consideration, haze is becoming serious in some countries, especially in China. Burning wood chip pellet is a better choice than coal. Last year, China has put out some policy to forbid burning coal in both urban and rural area, developing a new kind of environmental friendly energy is essential and emergent. Therefore, if you can't find a customer, you can also look at it in some places. Specifically, look at places such as schools, business units, hospitals, and research institutes that burn boilers. Protecting the environment is an obligation that every citizen of the city must fulfill. As the country calls for the prohibition of burning coal more and more stringent, the biomass pellet market grows bigger and bigger, so it does not need to worry about the sale of wood pellets.

Take the weather factor into consideration, haze is becoming serious in some countries, especially in China. Burning wood chip pellet is a better choice than coal. Last year, China has put out some policy to forbid burning coal in both urban and rural area, developing a new kind of environmental friendly energy is essential and emergent. Therefore, if you can't find a customer, you can also look at it in some places. Specifically, look at places such as schools, business units, hospitals, and research institutes that burn boilers. Protecting the environment is an obligation that every citizen of the city must fulfill. As the country calls for the prohibition of burning coal more and more stringent, the biomass pellet market grows bigger and bigger, so it does not need to worry about the sale of wood pellets.

However, some of the customers’ raw materials are wood scraps, because wood scraps are cheap and easy to purchase, then you need to add a wood chipper, and first put the wood off the specification The material is cut into chips and then crushed.

However, some of the customers’ raw materials are wood scraps, because wood scraps are cheap and easy to purchase, then you need to add a wood chipper, and first put the wood off the specification The material is cut into chips and then crushed.

The last factor, if the production of wood pellets exceeds 1 ton, a cooler is needed because the pellets have just been produced at a temperature of about 50-60 degrees, and after the pellets are produced, the pellets are steamed and cooled. The purpose is to cool the pellets, and use the wind to extract this part of the heat and steam to achieve the standard of direct pelleting and sales of pellets. If you do not cool, unless you are not eager to bag sales, water vapor and heat after bagging will seal moisture and affect the formation of particles. The last is the packaging machine, this one is chosen according to the customer.

Therefore, how much is a wood chip machine is not a specific number, it need to be based on materials, water content, with the appropriate equipment and so on.

Market of wood pellet

We have been asked many times by our customers whether wood pellet can sales well or not. Today and at here, we can tell our customers do not worry about the market of wood chip pellets. The wood chip pellet have a large market at home and aboard, biomass pellet has a wild application, it can be used for home heating, cooking, electricity generation and so on. Nowadays, the pellet demand in South Korea and European countries are extremely large, millions tons of biomass pellet are delivered to these countries.

What you need to know while choosing a wood pellet machine?

The raw material moisture requirement of wood pellets machine is very harsh, the moisture content of the material is too high, and the die hole will be blocked, resulting in the pellets not being produced. If the moisture content of the material is too low, if it is too dry, it is not easy to be formed, and the viscosity is not enough. The raw material moisture is generally 10% -15% before production. raw material moisture is the standard to suppress wood pellets, such as raw materials, high moisture, the material into the ring mold after the emergence of mold and slip phenomenon; pay attention to control the water before entering the machine, such as water is high slippage in the ring mold will occur, resulting in a phenomenon that is not easily discharged. If your raw material meets the requirements, a wood pellet mill can produce wood pellets. If they do not meet the requirements, so it is necessary to provide dryers and hot air ovens. Of course this is the case where your raw material is wood chips. If your raw material is wood chips (thickness less than 0.5mm) then it needs to be crushed, which means that it adds another process. Some of the customer's raw materials are bark. It is also possible to add a crusher.

The last factor, if the production of wood pellets exceeds 1 ton, a cooler is needed because the pellets have just been produced at a temperature of about 50-60 degrees, and after the pellets are produced, the pellets are steamed and cooled. The purpose is to cool the pellets, and use the wind to extract this part of the heat and steam to achieve the standard of direct pelleting and sales of pellets. If you do not cool, unless you are not eager to bag sales, water vapor and heat after bagging will seal moisture and affect the formation of particles. The last is the packaging machine, this one is chosen according to the customer.

Therefore, how much is a wood chip machine is not a specific number, it need to be based on materials, water content, with the appropriate equipment and so on.