How to judge a wood pellet machine from it’s spare parts?

The central part of a wood pellet machine is die. The quality of die directly influence of the operation of the pellet machine. Let me put it another way, the main factor that determines the actual output is the die. Be careful before selecting a wood pellet machine, do not forget check the qualification rate of pellet spare parts.

How can we judge the quality of pellet die?

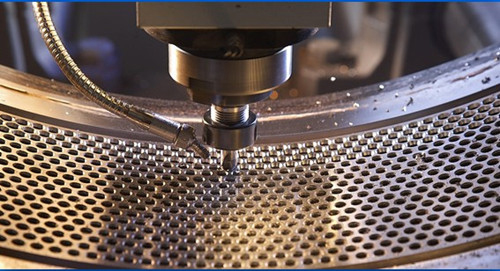

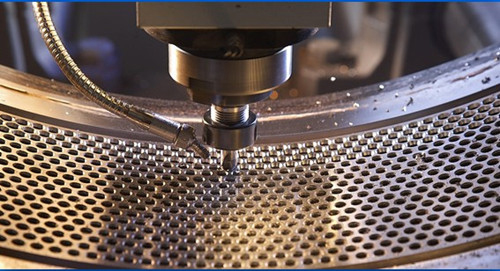

- Whether the surface of the die is fine processed.

- Whether the shape of die is exactly the same.

- Whether the hardness of the die has reached it’s standard.

- Check the tenacity of the die.

Characteristics of GEMCO pellet machine spare parts:

- Reliable alloy material. GEMCO pellet die adopts superior alloy, the products are firm and reliable. Selected reliable alloy suppliers, no worries about quality.

- Numerous elaborate experiments. We strive for progress in machine manufacturing. Our technology team keeps looking for new breakthroughs. Cooperate with our front line staff, combine with customers’ feed back, we continue to experiment and make improvements.

- Support of high tech machinery. Electrification operation, Computer manipulation. The thickness of dies are uniform, surfaces are smooth, the sizes of the die holes are unified and arranged in order. There will be no skew hole, block hole or overlapping hole, etc.

- Long working hours. Both side of GEMCO pellet die can put into use. according to the statistics, it can last 800 hours.

- Aperture customizable. You can customize the most suitable die holes according to your raw material or needs. GEMCO provide raw material test for you, if you need, please contact our customer service center, our staff is ready to help.

- Considerate after-sales service. If you need to change new die, brand new die produced by the original factory is your best choice. Change both roller and die at the same time, cause any of them is old or damaged will cause damage to the other and also influence the production of pellet. We also sell spare parts.